Week 10/6 - 10/10

- Adam Sayres

- Oct 10, 2025

- 2 min read

This week in Robotics, Mr. L had me steer away from the course to mill a separate part that he normally uses to teach students on the Tormach mill. This required watching two and a half hours of videos, but I made a mistake and watched one I didn't need to because it was a tutorial for a different machine. The part is called the Titan-1M and is part of the Titans of CNC CAM guides for 2.5-axis milling. We will be using the Tormach 770M CNC mill. Mr. L thought it would be a good idea to use this mill instead of the 1100M because it requires putting in the tools yourself instead of automatically like the 1100M does.

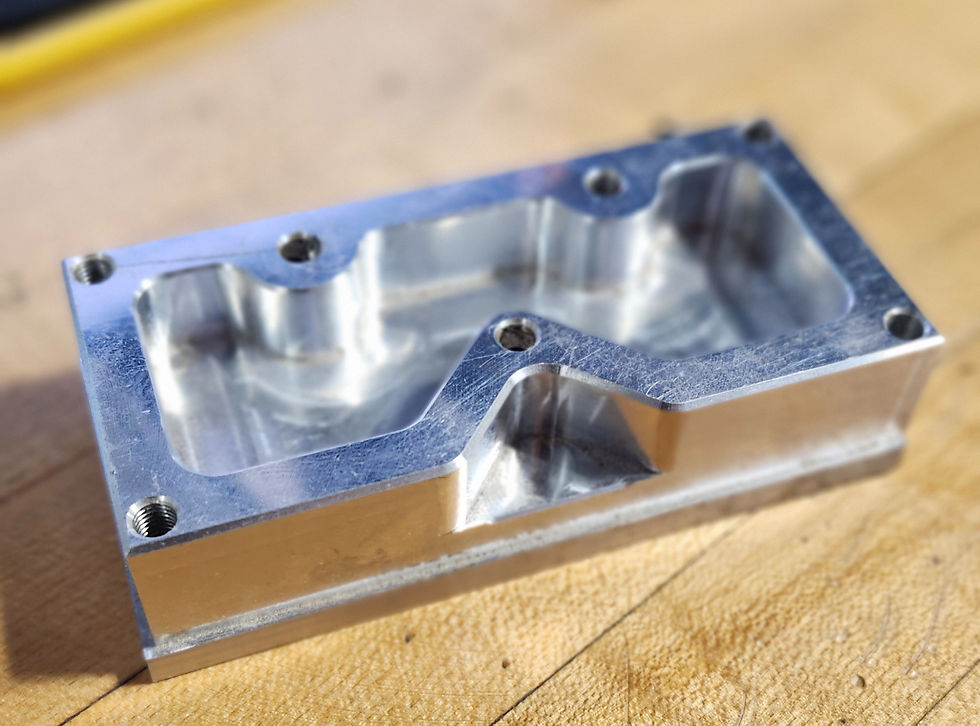

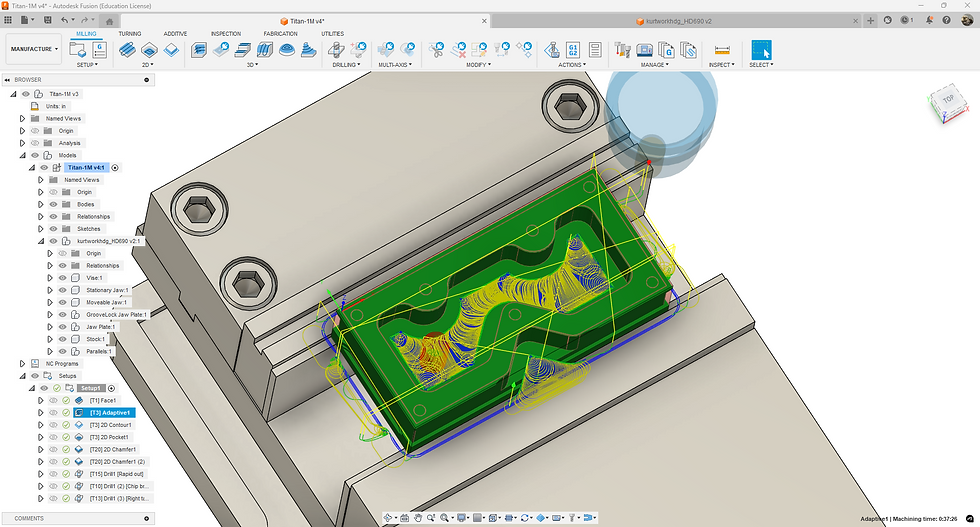

After modeling the part in the "design" tab of Fusion we moved to the "manufacture" tab to create the tool paths for the part. The videos went over the same types of toolpaths and information covered in the Autodesk course, but with a bit more detail, as this wasn't just a general overview. The biggest toolpath to do was the adaptive tool path as this roughs out the entire inside and outside pocket of our design. It uses a helix pattern to spiral down to where the bottom of the pocket is, then makes circles to cut out the rest. The pocket toolpath will then finish out these parts of the model at slower speeds to a get a cleaner, more finished design.

The final step is for the holes to be drilled in the part. This is a three-step process from start to finish.

Once the holes are added, the part is finished. All that is left to do is flip it over and face the bottom to get rid of the remaining part of the stock that was held in our vise.

After all the toolpaths were made, I had to watch just a few more videos. These taught me how to upload the 3D model of the vise that we use in the shop. They showed a bit more than just that by teaching how to use parameters to define different stock sizes and then how to easily insert the part you are making into the vise. With the parameters tool, only a few numbers need to be changed anytime I want to use a different stock size, which will be very convenient.

The last thing I had to do this week was to take the tools used in the Titans of CNC video and match them with similar tools that we have in the shop, since we are using different sets of tools. The next steps will be to cut the stock and the mill, and this project will be done.

Comments