Week 11/17 - 11/21

- Adam Sayres

- Nov 21, 2025

- 3 min read

This week Ben and I started by creating the cylinder on the mill. Although originally this was supposed to be turned on the lathe Mr. L thought it would be easier to just use the mill instead. The cylinder involves one big hole which is where the piston goes and then two smaller holes. One of these will get tapped and the other one will go straight through into the bigger holes to let air from the piston out through the upright. We were very focused when doing this so I didn't get any pictures.

The next step was to make the piston. This would get turned on the lathe and required Ben and I to learn how to use different parts of the lathe since we had never actually needed it before. The stuff we were doing was pretty simple since it just required facing the stock and then gradually reducing the diameter in the parts we needed.

The piston was going really well up until we were about to finish. Ben and I decided to check and make sure that we hadn't made the diameter two small since it needs to perfectly fit in the cylinder with no error. But unfortunately the piston was not the problem. When making the cylinder we had just used a 1/2" drill to make our big hole which doesn't exactly make it a perfect half inch. So in the end while the piston was only at 0.507" the cylinder had a 0.52" hole. There were two things we could do in this situation. Either we remake the piston to fit the size of the cylinder or remake the cylinder using a reamer to get a more perfect sizing. In the end we chose the cylinder option since we had plenty of 1" x 1" aluminum in the shop and no 5/8" steel bars.

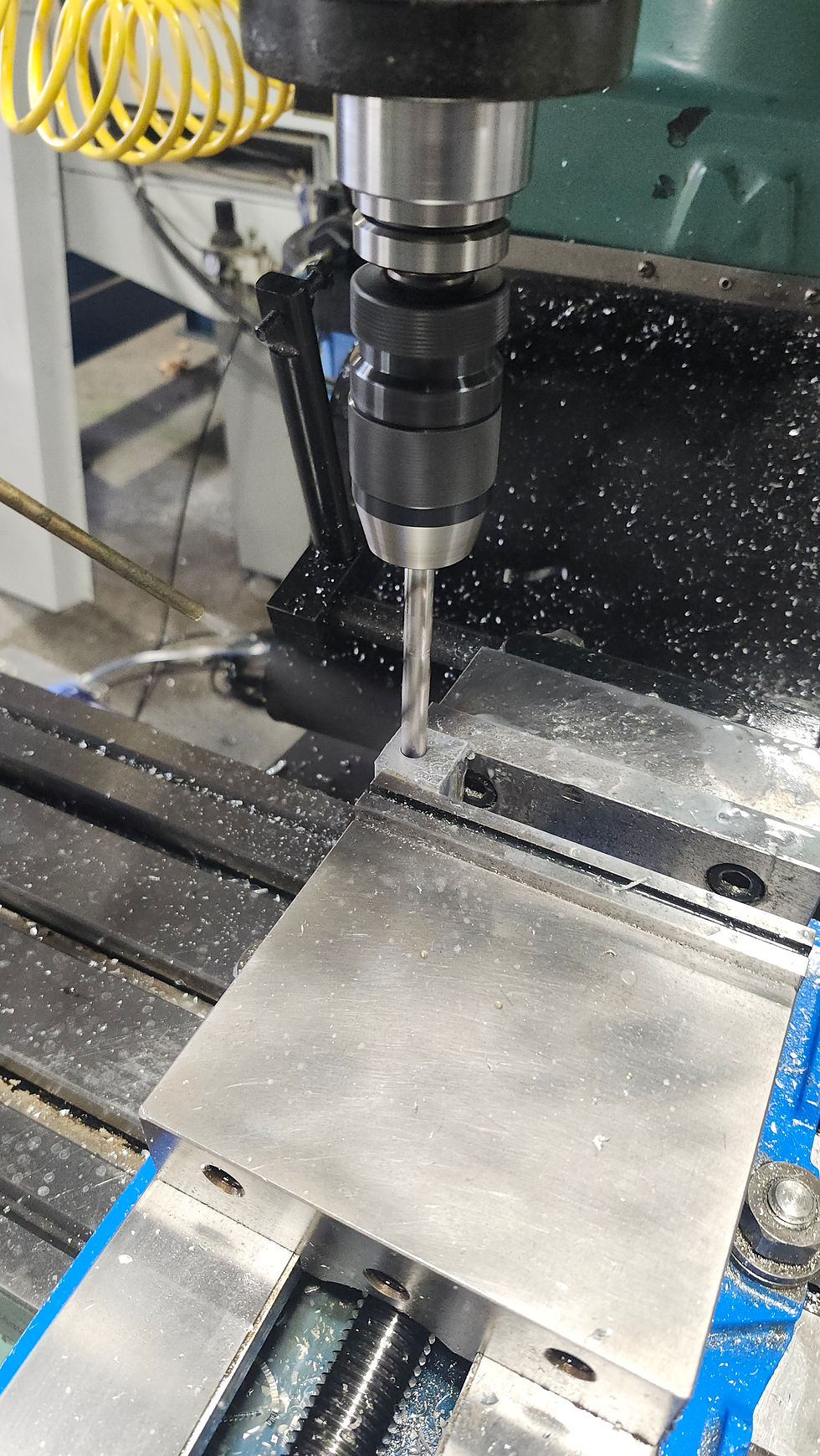

For this Mr. L suggested we use our Tormach mills so we could learn the different types of mills since we have both manual and more digital mills in the shop. Ben and I were taught many essential skills in how to do basic operations on the Tormach including making new tools and finding tool lengths which are crucial and help to make the mills more precise which is the general advantage over the manual mills. Another thing Mr. L taught us was how to use the automatic functions of the mill to go to an exact length we wanted to when drilling, essentially leaving the drilling up to the machine completely.

This didn't pan out in the end either. Something about the motor wasn't able to drill the 1/2" hole into the cylinder. Even using a smaller drill to step down to a closer size wasn't enough. The motor just wouldn't budge once put to the part. It wasn't a complete waste of time considering all the things we learned, but in the end Ben and I decided to try one more time on the manual mill.

We were extra careful using two different drills to step down to the correct size and that will be a 31/64" drill. This process worked great and our hole was the exact size it was supposed to be. After this we will use a half-inch reamer to get to the exact right size and then finish doing the piston. Hopefully after all this everything will go correctly and we can move on to other parts of the steam engine. In terms of the trebuchet metal fab is still working on cutting the pieces and once they finish Ben and I can decide with them what we need to do in our own shop.

Comments