Week 9/29 - 10/3

- Adam Sayres

- Oct 3, 2025

- 2 min read

For the start of this week I edited and changed some things about my pass-through fidgets. The cone had originally not worked because I hadn't adjusted the tolerances accordingly so the cones were getting stuck together. Mr. L. taught me how to use the offset faces tool to remove more from the inside of the outside part of the cone, which allowed them to work nearly perfectly once put together.

The pawn shape I made from the game of chess also had some complications. When originally making it the video I used had made the bottom connection too thin for the outside piece, which resulted in our printer not being able to print it. Once this was pointed out to me by a classmate I figured all that was needed was a little ring on the bottom to connect everything together. This worked great, but unfortunately, when the printer got to the top, there wasn't enough support, which caused the top of the print to fail. I might go back to edit this but since I have moved on to a different project, there is very little chance of this.

The next part of the week, I started working on the CAM (computer-aided manufacturing) course for 2.5-axis milling. The 2.5 axis refers to being able to move in the X, Y, and Z axes, but not being able to move the Z axis while also moving the X and Y axes. This will be important for learning how to use the Tormach mills in our shop. The first part of the course was learning about how to make and read different documents that are used when planning to do something on the mill. This included tool planning and dimensioning.

The second part was a bit more about how to do different types of joints and motion links. This was the same stuff that I had learned in the CAD Associateship Course, but it was a refresher for people who hadn't done that. After focusing on that, I learned about different tools in the Machining tab of Fusion and how to use the Measure tool to plan what type of tools will be used to do different cuts, and then how to import those into a tool library in Fusion.

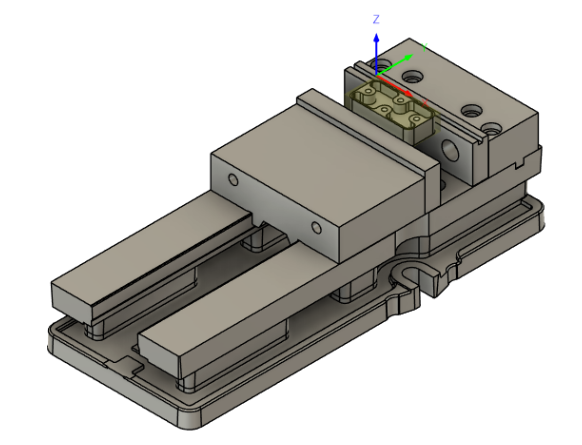

After I had learned how to plan and import tools into Fusion, it was time for the next big step. Planning and then simulating tool paths. I go to learn some of the most important tool paths in Fusion and why you would use one over the other in certain situations. Then it taught me how to import the machine I would use for the job and how to would look when milling in the machine. This is crucial when I am planning to mill parts in the machine and need to know what is best to use to keep tools from breaking or the machine in general.

Comments